Printing Tips

Introduction

A collection of printing tips gleaned from the experience of reprappers.

Upgrading Slic3r

Helpful Note for upgraders from Andy H: It's worth starting again with the settings with each new Slic3r release. It seems Slicer, on occasion, gets confused with old settings. Delete your old settings, or run the print settings wizard, to start afresh. It took me ages to fix a bridging problem with 0.9.2; old settings from 0.8.x seemed to upset it.

Temperature setting

Ginjaian: Plastic filament, both PLA and ABS have two temperatures that effect their consistency. The first is the 'glass transition' temperature, where the plastic changes from solid into a molten or rubber like state. For PLA this is usually around 70C, and the bed temperature needs to be around this temperature for it to stick well. It is a little higher for ABS. The second temperature is the melting point, above which we extrude plastic, for PLA this is around 160, for ABS it can be as high as 220C. The exact temperature will depend on the exact chemical consistency of the plastic, as there is a wide variation.

BusError: with the new PLA from Paul (Cynar): to make sure it sticks to the glass, use 80C as bed temp... even at 70 sometime it unstick itself, even from ground glass bed. So black PLA, melt temp 160, bed first layer 80C, further layers 70C

Calibration

Ginjaian - Try extruding first. Move the nozzle up to say 30mm above the bed. Poke some filament down it. Heat up to 180C, which should be plenty. Press the Extrude button to extrude some filament, check it's all working. Don't leave filament at high temp for too long, ie over 3 minutes, without moving, as heat travels up the barrel and into the extruder eventually.

Another tip from Ginjaian - I don't have any endstops, so setting up after turning on can take a couple of minutes. I just centre the nozzle over the bed, move it down until it traps a piece of paper, and set G92 X100 Y100 Z0

Swapping filament

Ginjaian: I have found I can get a pretty good clearance of PLA by heating to 80C, then retract 20mm, then open the extruder idler and pull the filament out. It usually pulls out right to the nozzle for me. I'm not sure if this works for ABS, or at what temperature.

Improving Quality

BusError: hard rubber pads under the printer divides the noise by easily two AND have mostly solved the "ripples" imoressions I was seeing in my prints

BusError: Slicer can make a nice 'raft' that helps hold down small pieces, just use skirt distance = 0.2, skirt count = 5 (or more)... the skit barely sticks to the outside, but just enough to help

BusError: A piece of felt and two cable ties makes a nice dust/grub catcher when wrapped around the filament

Things to watch for

Unspooling filament: There are many options for mounting your spools of filament, just search Thingiverse for some ideas. Note that if you are printing on an unattended machine that filament flow is critical. If it catches, is too twisted or too tightly bound up in the centre of the spool then the Z axis can be pulled upward or the hob bolt gummed up.

Things to Print

If you are looking for more info and ready made things to try printing - here are some links to sources

RepRap.Org

Thingiverse code repository

- Hannah's record of all our things RepRap

- Xander is another local builder

Places to buy stuff

EMakerShop

RepRapKit

BitsFromBytes

Faberdashery - a small company in the South West who do PLA in loads of colours and by the metre. They are also on the way to recycling PLA, which is something to be supported

Giving Back to TVRR

An important part of the TVRR Community is the stuff that is created and donated, here are some examples:

Barnaby has created an Android App (DroidRap Link) for RepRap as discussed here

Michel has created a number of alternative design parts for Z, X and Y axes.

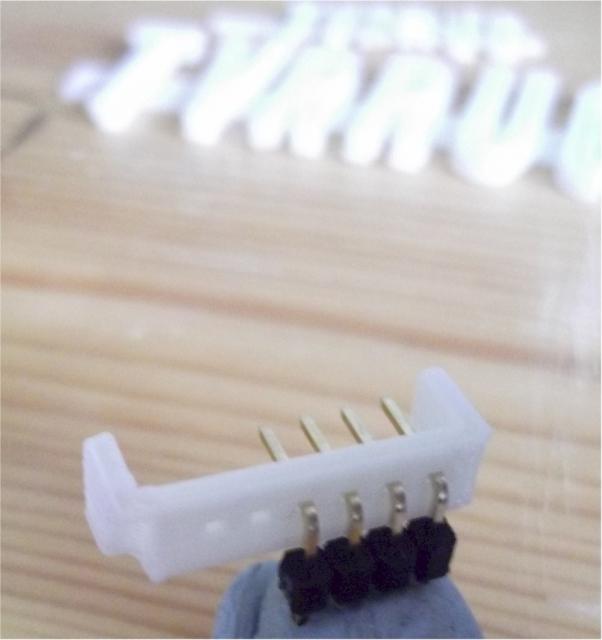

Mike has created a 'shell' for the FTDI connector on the OMC1, the pic is showing how it slides over the pins. The SCAD file is here

Mike has created a 'shell' for the FTDI connector on the OMC1, the pic is showing how it slides over the pins. The SCAD file is here